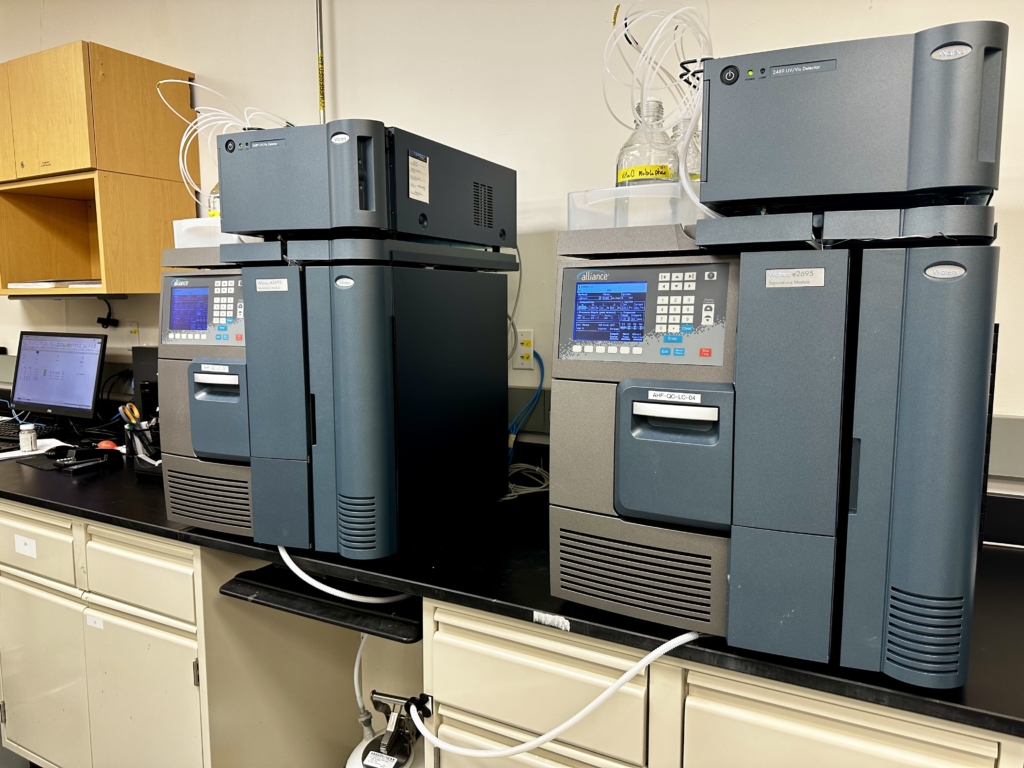

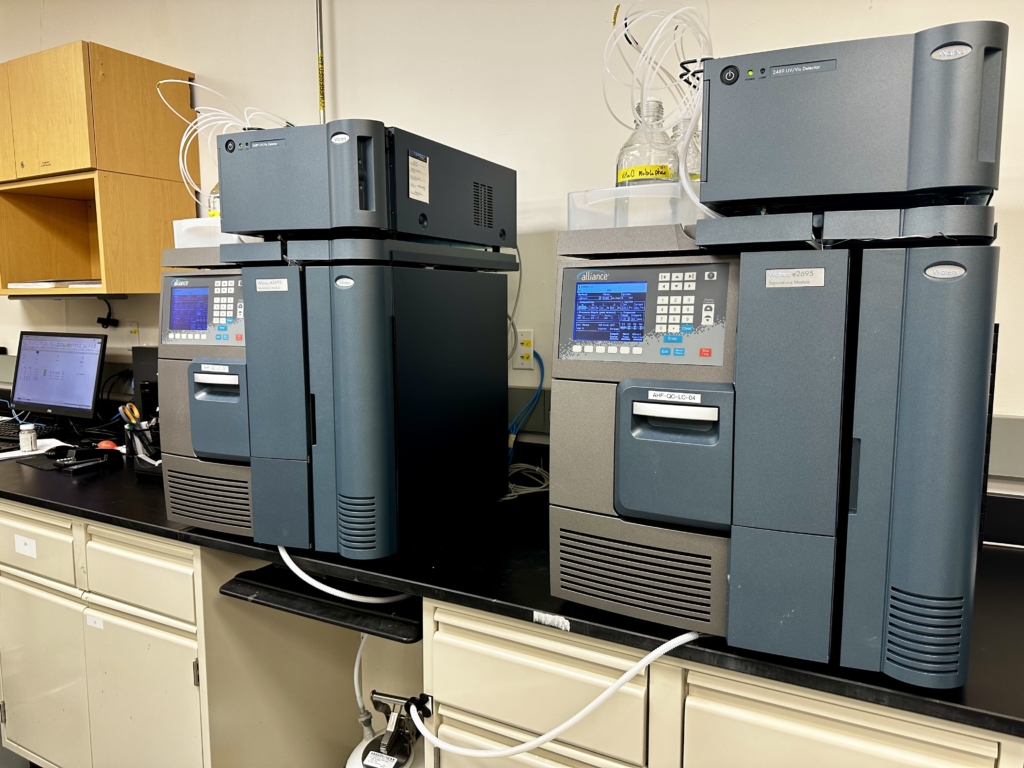

Analytical Testing

Our in-house QC lab and innovation center offers

analytical testing to validate both raw materials and finished products to meet required specifications for identity, strength, purity and physical composition.

Our technical experts can help you develop a robust testing portfolio that perfectly aligns with the specific needs of your company and products.

• Identification analysis and verification of all nutritional ingredients.

• Potency (Assay) testing to confirm the strength of your active compounds through all stages of production.

• Purity testing to analyze the presence of heavy metals, microbials and confirmation that your products are free of other potential contaminants.

• Physical analysis of essential properties such as moisture content, loss on drying, water percentage, particle size distribution, density, disintegration and more.

Our extensive range of methodologies will verify and validate your label claims with the proof that an ingredient was recovered at the proper dosage after the manufacturing process completes.

All our products meet the quality performance standards published in the United States Pharmacopeia (USP). These standards specify allowable rates of disintegration, dissolution, dosage strength, range of acceptable impurities and microbiological value.

• HPLC with UV/PDA & MS Detection

• FTIR

• TLC

• UV-VIS

• GC

• KF Titration

• Stability Chamber (Climate Controlled)

• Moisture Balance

• Friability Apparatus

• Hardness Tester

• Dissolution & Disintegration

• Raw Material Release Testing

• Finished Product Testing

• Stability Studies (Shelf-Life Testing)

• Method Development & Validations

Analytical Testing

Our in-house QC lab and innovation center offers analytical testing to validate both raw materials and finished products to meet required specifications for identity, strength, purity and physical composition.

Our technical experts can help you develop a robust testing portfolio that perfectly aligns with the specific needs of your company and products.

• Identification analysis and verification of all nutritional ingredients.

• Potency (Assay) testing to confirm the strength of your

active compounds through all stages of production.

• Purity testing to analyze the presence of heavy metals, microbials and confirmation that your products are free of other potential contaminants.

• Physical analysis of essential properties such as moisture content, loss on drying, water percentage, particle size distribution, density, disintegration and more.

Our extensive range of methodologies will verify and validate your label claims with the proof that an ingredient was recovered at the proper dosage after the manufacturing process completes.

All our products meet the quality performance standards published in the United States Pharmacopeia (USP). These standards specify allowable rates of disintegration, dissolution, dosage strength, range of acceptable impurities and microbiological value.

• HPLC with UV/PDA & MS Detection

• FTIR

• TLC

• UV-VIS

• GC

• KF Titration

• Stability Chamber (Climate Controlled)

• Moisture Balance

• Friability Apparatus

• Hardness Tester

• Dissolution & Disintegration

• Raw Material Release Testing

• Finished Product Testing

• Stability Studies (Shelf-Life Testing)

• Method Development & Validations

• Raw Material Release Testing

• Finished Product Testing

• Stability Studies (Shelf-Life Testing)

• Method Development & Validations